PT. Laser Indonesia Multiteknik becomes the leader of laser cladding technology in Indonesia, capable of cladding materials like inconel 625, stellite 6, SUS316, tungsten carbide etc for a high-quality surface addition of material.

The laser cladding process is also known as Directed Metal Deposition and is useful for protection against corrosion, abrasion and impact, depending on the material used. Our mobile system can be deployed to all over Indonesia.

Laser Cladding Materials we have in stock

- Stellite 6 (3mm max. thickness)

- Stellite 12

- Inconel 625

- Tungsten Carbide NiCrSiN CTC 40/60

- Rockit 401 - FeCrNiMo (Hard choriming substitute)

- 316 Stainless Steel

- 420 Stainless Steel

- 431 Stainless Steel

- Aluminium (Rod)

With laser cladding, you can now repair your worn-out parts, hence extending the lifespan of your parts/equipment. The process of repairing of parts should reduce your cost significantly, compared to replacement. Furthermore, the repair process can upgrade the quality of your parts, for example by increasing strength, adding corrosion resistance or even improvement in shape and design.

Please note that we are in no position to promote ourselves as expert of the product you wish to repair. We are only providing laser cladding as a service and is not responsible for whatever effect and consequences to the base material. Please make sure you have an expert of the product on hand.

The repair is done with robot using diode laser, delivering metal coating with minimal heat input compared to other welding process. The result is a very neat welding track, less distortion to your part and most importantly prevent heat damages to your material.

Laser Indonesia offers a unique solution to this, in which we are able to travel to your site and deploy. This opens up the potential of repairing extremely large equipment in-situ. This will simplify your logistic demand and schedule management for your large and complicated repair or over-haul projects. Us working on your site, also ensure your full control of the process. As such, the repair process can be fully and closely monitored.

We also offer very specialized conventional TIG/MIG welding process that delivers AC or DC pulsed welding and high welding power to repair equipment with very specific requirements.

System Specification

Laser Source: Coherent Highlight DL4000HPS with 4000w @ 940 nm laser.

Cladding head: Coherent-LASAG with Fraunhofer ILT 3 axis powder supply. With 3mm beam diameter.

Control: KUKA KR20-1810-2.

For more infomation, please contact us at info@laserindonesia.com

or Call or Whatsup at +62(812)563-2349.

Cladding result with Rockit 401 (HRC 50-54)

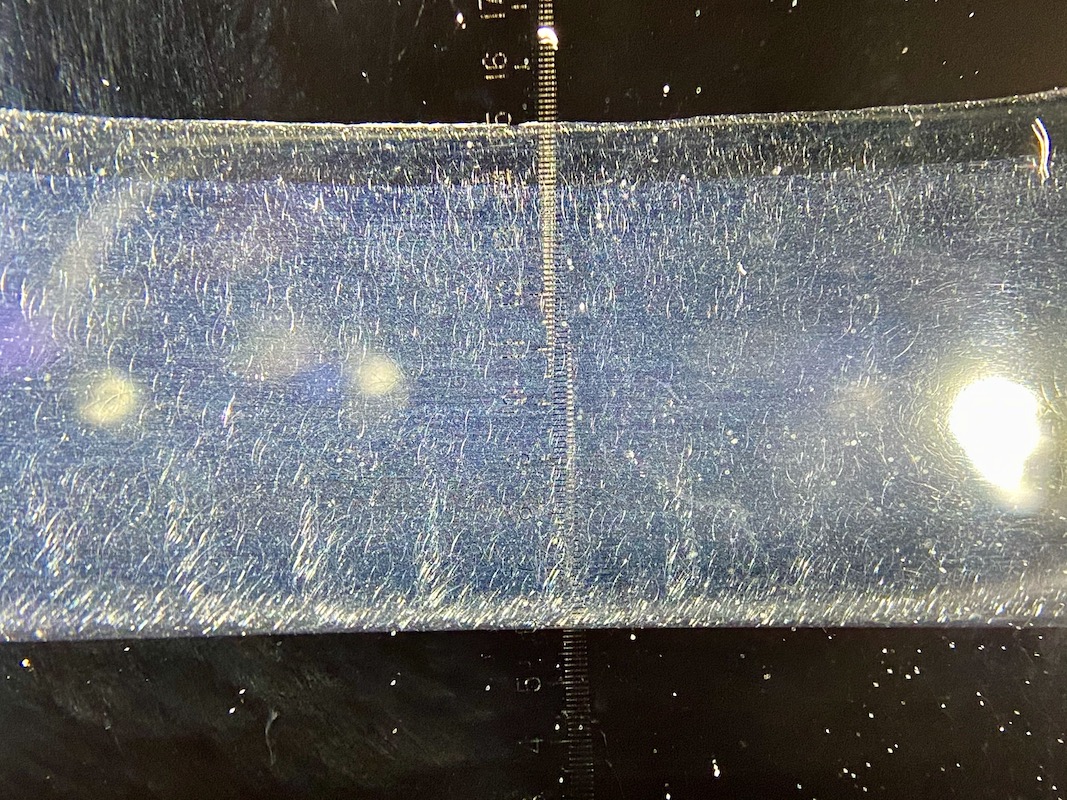

Surface of Cladding with stellite 6.

Close-up of cladding result with Stellite 6 from a differnet angle.

2mm thick cladding on 2mm thick mild steel pipe. Dillution is minimal with laser cladding.

Distortion is from lens, not from cladding process.